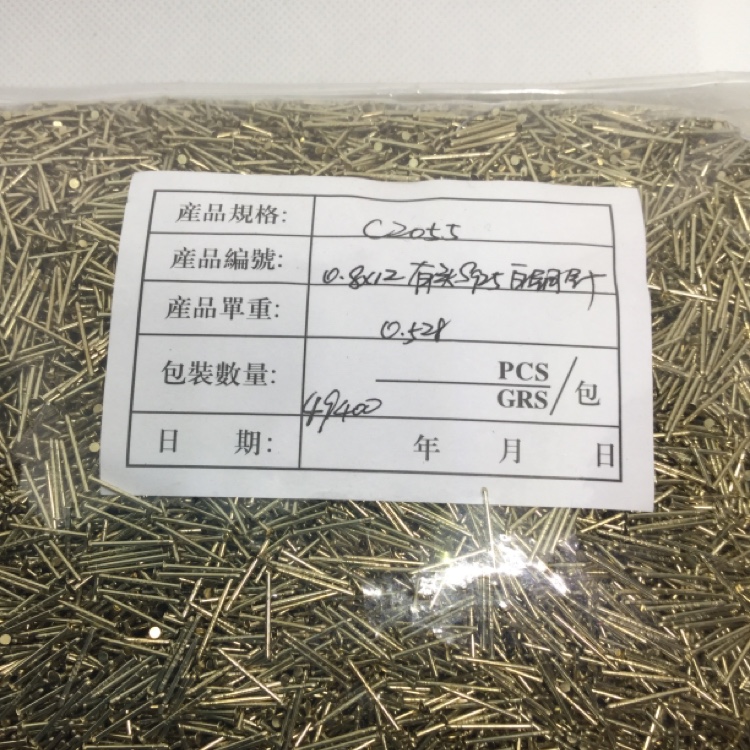

Factory Direct S925 White Copper Needles – 0.8*12 Head for Jewelry Making

It’s just past dawn. The studio is quiet, save for the soft clink of beads and the rhythmic glide of a needle through thread. In this stillness, a jeweler leans over her workbench, eyes focused on a nearly finished necklace—each tiny bead placed with intention. It’s not the gemstones or the design that will determine its perfection, but something far smaller: the needle in her hand.

This is where craft meets precision—the moment when a simple tool becomes the silent architect of beauty. Enter the S925 white copper needle, an unassuming yet indispensable ally in the world of fine jewelry making. Not flashy, never credited, but absolutely essential. These are not just needles—they’re the invisible threads holding masterpieces together.

From Factory to Workbench: The Warmth of Direct Craftsmanship

Imagine walking into a sunlit workshop nestled in a quiet industrial district. The air hums with the gentle sound of metal being shaped—tiny needles spinning under expert machines, each tip polished to mirror-like smoothness. Workers inspect every piece under bright lights, ensuring no burrs, no inconsistencies. Then, row after row of needles are neatly packed, ready to travel straight to artists’ hands—no warehouses, no resellers, no markup.

This is what “factory direct” truly means. By cutting out layers of distribution, we preserve both quality and affordability. What reaches your workbench isn’t a product diluted by middlemen—it’s craftsmanship preserved from origin to application. You’re not just buying a tool; you’re receiving a piece of a process built on care, consistency, and respect for the maker.

0.8×12mm Tip: Precision Expressed in Millimeters

The numbers tell a story: 0.8mm in diameter, 12mm long tip. At first glance, they seem technical—cold metrics. But for jewelers, these digits speak a language of control and possibility. A 0.8mm shaft slips effortlessly through even the tiniest seed beads without fraying thread. The extended 12mm head allows deeper reach into tight loops and multi-strand weaves, giving you command over complex patterns like peyote stitch, right-angle weave, or micro-soldered frameworks.

Compare this to standard needles often found online—either too thick to navigate delicate components or too short to maintain grip during extended use. This specific dimension strikes a rare balance: slender enough for finesse, long enough for function. Whether you're weaving a bridal tiara or assembling a museum-worthy pendant, this needle doesn't get in the way—it disappears into your rhythm, doing exactly what it should.

S925 White Copper: Where Strength Meets Grace

You might expect sterling silver for high-end tools—but here’s the secret: S925 white copper often outperforms it in real-world use. Engineered with a proprietary alloy blend, it offers superior resistance to oxidation compared to pure silver, meaning your needles stay bright and clean after repeated handling. More importantly, it balances hardness and flexibility perfectly—firm enough to pierce tightly wound coils, yet resilient enough not to snap under pressure.

Ask any seasoned artisan: the frustration of a bent needle mid-design can derail hours of work. With these, you feel confidence in every push-through. They don’t twist, they don’t dull quickly, and most importantly, they don’t compromise your flow. After dozens of passes through silk thread and micro-beads, they perform as if new. That’s not luck—it’s material science meeting artisan need.

The Silent Heroes Behind Stunning Creations

Take Lena, an independent designer preparing for her debut at a European craft fair. Her collection features cascading necklaces woven with Japanese delicas and Swarovski crystals—each piece requiring hundreds of precise stitches. When her usual supplier delayed shipment, she switched to these factory-direct white copper needles on a recommendation from a colleague. The result? She completed her series two days ahead of schedule, citing their “unbelievable smoothness” and reliability.

Or consider Mark, a hobbyist who’d struggled for months to complete a Byzantine chain braid. He’d tried three different brands—each either too stiff or too fragile. On his fourth attempt, armed with the 0.8×12 S925 needles, he finished it in one sitting. “I finally felt like I was guiding the thread,” he said, “not fighting it.”

More Than Tools—Extensions of Your Creative Pulse

Great tools don’t announce themselves. They become extensions of thought, translating vision into motion. When a needle moves like water through fabric, your mind stays ahead of your hands, dreaming up the next curve, the next pattern. That’s the experience users describe: a sensation akin to a fountain pen gliding across paper—effortless, intuitive, responsive.

In studios around the world, creators report fewer hand cramps, reduced thread breakage, and faster completion times. It’s not magic—it’s thoughtful engineering meeting ergonomic understanding. And once you’ve worked with them, going back feels like writing with a blunt pencil.

Why Top Studios Are Making the Switch

Word spreads quietly among professionals. No loud campaigns, no influencer hype—just consistent results. Studios now stock these needles as standard issue. Instructors recommend them in advanced beading courses. Craft communities tag them in tutorials with comments like “game-changer” and “why didn’t I find these sooner?”

The reasons are practical: low breakage rates, batch-to-batch consistency, and a sleek, non-reflective finish that doesn’t distract under studio lighting. For businesses, that means predictable costs and fewer workflow interruptions. For artists, it means trust—knowing your tools won’t betray you at the final stitch.

To Your Next Masterpiece: A Letter in Every Needle

Every great creation begins with a decision—not just of design, but of materials. Choosing a needle may seem small, but it sets the tone for everything that follows. To treat such choices lightly is to risk friction where there should be flow, doubt where there should be certainty.

So here’s an invitation: start honoring the details. Let your tools reflect the dignity of your craft. Each of these S925 white copper needles carries more than metallurgical excellence—it carries the potential of what you have yet to make. Waiting in their tips is not just steel, but silence filled with light, ready to pull your next idea into form, one perfect stitch at a time.