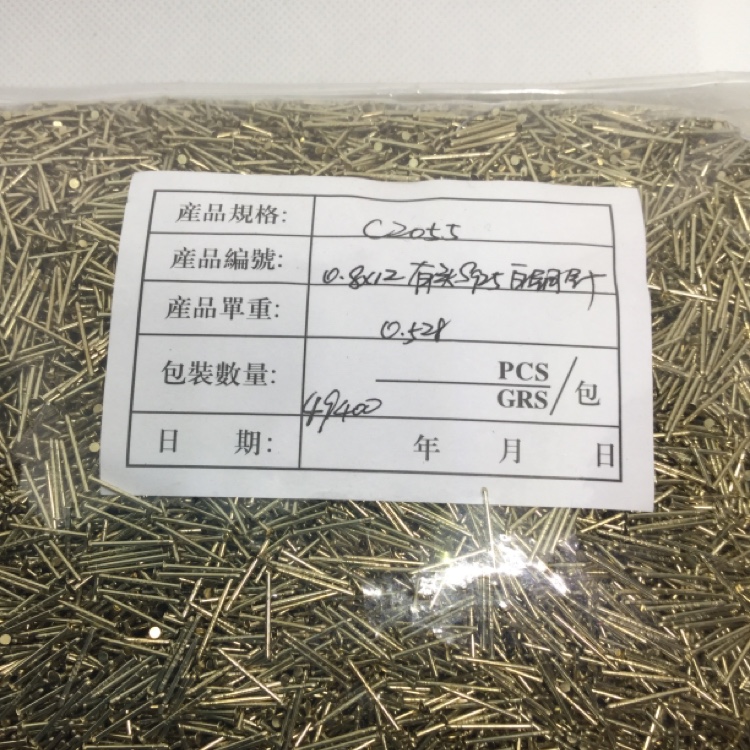

Directly hit the source: from the manufacturer to the customer's high quality copper needles

Learn more about how we deliver the highest quality S925 cupronickel needles directly to our customers. By reducing unnecessary middlemen, we are able to offer competitive prices while maintaining superior product quality. Each product has been carefully selected and rigorously inspected to ensure that what you receive is top quality.

Material Choice: Why Choose S925 White Copper?

to explore why we will choose S925 white copper as the main raw material. This alloy not only has excellent physical properties such as high strength and good ductility, but more importantly, it has excellent corrosion resistance and attractive metallic luster. Whether it is used to make exquisite jewelry or other precision parts, S925 cupronickel is the ideal choice.

The Secret Weapon Behind Craftsmanship

Uncover what advanced equipment and technology on our production line help to create such a perfect white copper needle. The automated production line with high-precision molds, coupled with professional technical personnel to monitor and guide the whole process, together cast a stable and efficient production capacity team. Do not let go of every detail, and strive to do the best.

Strict quality inspection: never compromise on product quality

Describe in detail how our strict inspection process is carried out-from the inspection of raw materials to the final process before the finished product leaves the factory. The use of high-tech instruments for comprehensive analysis and testing, and the establishment of a multi-level audit system to ensure that non-conforming products never go out. This rigorous approach allows us to confidently introduce absolutely reliable products to the market.

Wide range of applications: not just in the jewelry industry

Although this type of high-quality white copper needle has a significant performance in the jewelry manufacturing industry, in fact, its use is far more than that. Due to its unique properties, it also has excellent application examples in many high-end industries such as watch assembly and medical device manufacturing. This article will take the reader a glimpse of these little-known but vital application scenarios.

The Story Behind the Price Advantage

Analyze how we can achieve a lower cost structure while maintaining a high level of quality. Thanks to economies of scale coupled with the effective implementation of the lean management model, we have been able to continuously optimize operational efficiency and reduce unit costs, thus being able to offer more profitable pricing solutions in the market without sacrificing any quality standards.