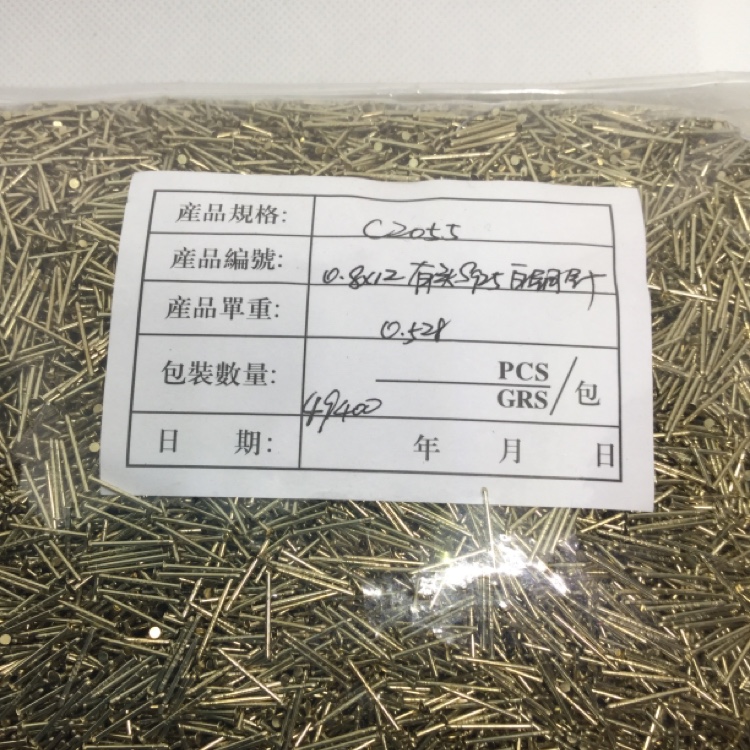

high precision jewelry processing necessary: factory direct 0.8*12 S925 copper needles

In the world of jewelry processing, every tiny detail may determine the overall texture of the finished product. And a high-quality tool can make your work get twice the result with half the effort. Today we will focus on this exquisite product from the factory-0.8*12 S925 white copper needles , and discuss in depth why it has become the first choice for many craftsmen.

the core of precision technology: the unique performance analysis of 0.8*12 S925 white copper needles

The S925 white copper material is known for its excellent corrosion resistance and hardness, which makes the white copper needles made of it extremely durable and stable. In addition, the size of the product is designed to be accurate to the millimeter level, and the head is processed with advanced polishing technology to ensure a smooth experience during operation. These characteristics together constitute its unparalleled advantages.

From manual to mechanical: Diversified application scenarios of this cupronickel needle in the jewelry industry

Whether it is hand-carved or mass-produced with modern equipment, this cupronickel needle can meet different needs. For small studios, it can assist in complex mosaic tasks; for large processing plants, it can be used as a key component to participate in automated processes. Regardless of the size of the operating environment, it has always demonstrated strong adaptability.

The ultimate: how to use this tool to improve the quality and speed of jewelry production

With this high-performance white copper needle, producers can greatly improve work efficiency while reducing errors. For example, in the fixed part of a diamond or other gemstone, its precise positioning function can make each step more accurate and reliable. At the same time, because the surface is smooth and flawless, it can effectively reduce the risk of damage to raw materials, thereby further ensuring product quality.

discerning pros and cons: detailed explanation of key indicators for purchasing high quality white copper needles

When faced with a wide variety of market choices, it is particularly important to identify truly high-quality products. The first thing to pay attention to is whether the material is clearly marked and conforms to the industry standard (for example, this product adopts S925 grade); The second is to observe whether there are defects in workmanship, including but not limited to whether there are burrs in the tip part. Finally, it is necessary to consider the brand credibility and after-sales service level and other factors of comprehensive judgment.

The secret of lasting sharpness: professional advice for daily maintenance and extended service life

In order to make the best use of your investment, please pay attention to the correct maintenance method. After each use, the residual substances should be cleaned in time to prevent oxidation reaction, and stored in a dry and ventilated place to avoid moisture erosion. In addition, regular application of a small amount of anti-rust oil can also play a good protective effect.

in short, this 0.8*12 head S925 white copper needle has won wide recognition in the industry for its excellent quality. If you are looking for an efficient and stable processing tool, then don't miss this excellent choice!