Revealing White Copper Needles: Why S925 Becomes Industry Benchmark

The white copper needle of the S925 logo has long been recognized by the industry as a symbol of high quality standards. This material stands out for its unique gloss, excellent wear resistance and corrosion resistance, and has become the preferred raw material in many industrial fields. Especially in the fields of jewelry inlay and precision electronic assembly, it is one of the indispensable core components.

S925 is not only a simple number code, but also represents an attitude of excellence and the spirit of unremitting pursuit of quality. Compared with ordinary metal products, S925 white copper needles can better adapt to the complex working environment, thus significantly improving the quality stability and aesthetics of the finished product.

From Material Selection to Molding: The Birth Journey of high quality White Copper Needle

Each S925 white copper needle has undergone a series of rigorous production processes before it is finally presented to you. The first is to control the quality of materials from the source and select high-purity cupronickel alloys that meet international standards; then enter the high-temperature smelting process, in this stage, the impurities are completely removed and the chemical composition is evenly distributed; then the grains are refined through multiple cold drawing processes, further enhancing the mechanical strength and toughness.

In addition, in order to meet the individual needs of different customers, we will also carry out special treatment on the front layer according to different purposes, such as nickel plating or polishing, so as to make every detail perfect.

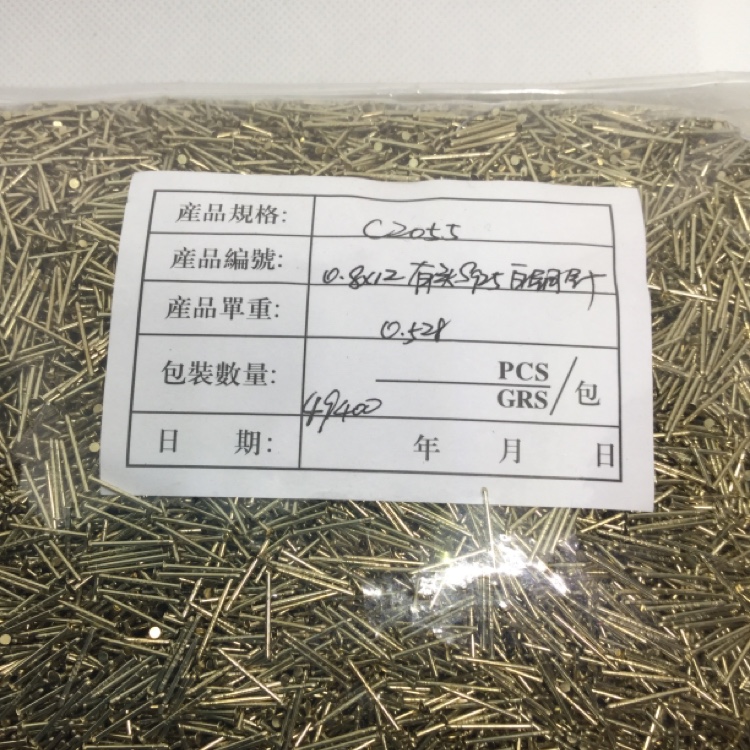

the secret of precise size: the ingenuity behind 0.8*12 heads

When we refer to the specification parameters of "0.8*12 heads", it actually means that the diameter of a single needle is 0.8mm, and each batch must strictly follow this value to control the error range not to exceed ± 0.02mm. Such precision requirements are by no means easy, behind the reliance on modern CNC equipment combined with the experience of senior technical personnel to work together.

Not only that, but also check whether the head shape is regular and consistent before assembling the kit to ensure a long-lasting and stable use experience. It is such a rigorous and meticulous operation process that has created the highly praised product image today.

Advantages of Factory Direct Sales: Transparent Price and Reliable Guarantee

As a company committed to providing quality services, we always adhere to the sales model of direct manufacturers to consumers. This method can not only greatly reduce the intermediate circulation cost, make the terminal price more competitive, but also facilitate the establishment of a more compact and efficient after-sales feedback mechanism.

Every buyer will enjoy one-to-one exclusive customer service support and a comprehensive return and exchange policy to protect their rights and interests from damage. Whether you are a first-time contact or a long-term partner, we will treat every opportunity with the same enthusiasm.

Practical use case: See how these customers benefit from S925 white copper needles

Mr. Zhang is the person in charge of a small jewelry processing factory. Since switching to our S925 white copper needles, he obviously feels that his work efficiency has been greatly improved. "In the past, the construction period was often delayed due to needle breakage, but now this situation almost does not exist." He said, "and because the product quality is stable and unified, it also reduces the number of rework in the later stage and saves a lot of labor expenses."

another Lao Li from the electronics manufacturing industry said: "this batch of customized models is especially suitable for fixing the micro components on the circuit board. the installation process is very smooth without any stuck phenomenon." It can be seen that whether in the field of traditional handicrafts or the forefront of modern science and technology, S925 white copper needles can always find their own luminous stage.