As an important tool in the field of jewelry processing, S925 white copper needles have won the trust of many craftsmen with their unique performance and excellent quality. This high quality white copper needle not only has excellent wear resistance and corrosion resistance, but also has excellent electrical conductivity, making it a benchmark product in the industry.

The choice of top craftsmen: revealing the unique advantages of S925 white copper needles

The reason why S925 white copper needles are widely favored is inseparable from its excellent material properties and precise design. This needle is made of high-quality white copper alloy to ensure the stability of long-term use. In addition, its slim and sharp tip can easily penetrate a variety of materials without damaging the surface texture, making it ideal for delicate manual operations. Whether in the production of rings, earrings or pendants and other complex shapes, can play an unparalleled advantage.

Go deep into the workshop: understand the production process behind high quality white copper needles

Each root must undergo strict quality inspection before leaving the factory, including precise measurement of dimensions, hardness testing, and appearance inspection. The entire process is completed using advanced automated equipment and manual review methods to minimize the error rate and ensure that the quality of each batch of products delivered to customers is consistent.

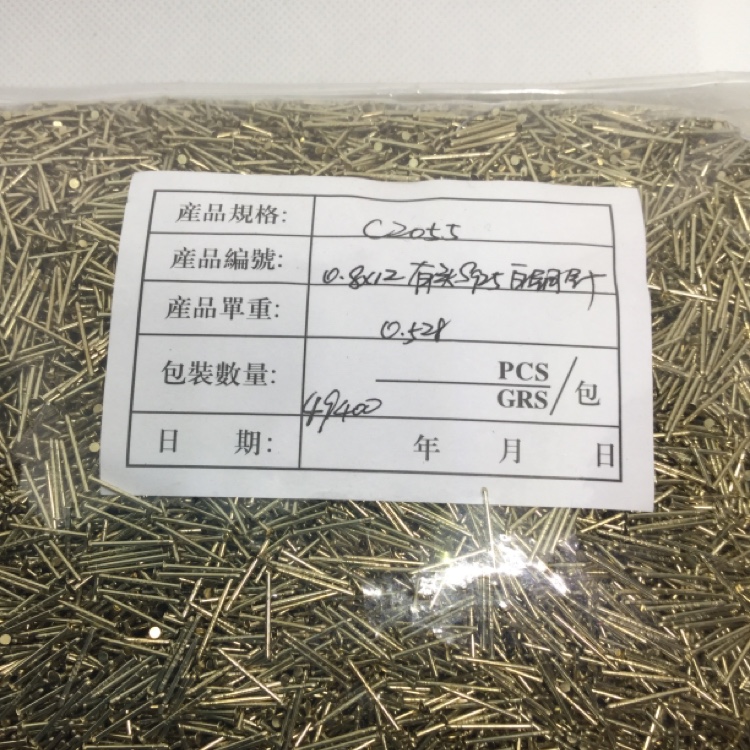

Data Talk: Why 0.8*12 Head Specification Becomes Industry Standard

After years of market verification and technology accumulation, the most popular S925 white copper needle specification has been determined to be 0.8mm diameter × 12mm length (the so-called "0.8*12 head"). This design takes full account of the demand balance point in the actual application scenario: it not only meets the strength requirements required in most cases, but also takes into account the space efficiency considerations for portable storage.

Practical Application Analysis: Discussion on Widespread Application Scenarios in Jewelry Processing and Other Fields

In addition to the traditional gold and silver utensils, modern technology has also opened up many new uses for this type of product. For example, such special profiles can be selected when precision punching is required during the assembly process of electronic components. In addition, some special crafts such as embroidery picture frame fixing nails can also be seen in their figures... It can be said that as long as there are places involving subtle parts of work, these little guys will be found busy and active!

Customer Voice: Real User Evaluation Shows Product Reliability and Durability

"Since switching to S925 white copper needles provided by your factory, the work efficiency has been significantly improved by nearly 30%!" A professional jewelry designer from Shenzhen said so. "In the past, broken needles often occurred, but now there is basically no need to worry about this problem." Another senior craftsman also added: "and the packaging is also very considerate, every time I receive the goods are intact, really satisfied."