As a highly respected material, S925 white copper stands out for its elegant appearance and excellent performance, and has gradually become the first choice for high-end craft manufacturers. Its luster is soft and durable without discoloration, and it has the characteristics of strong corrosion resistance, which is very suitable for long-term use. Whether it's jewellery inlays or delicate hand-sewing tools, the S925 cupronickel offers impeccable support.

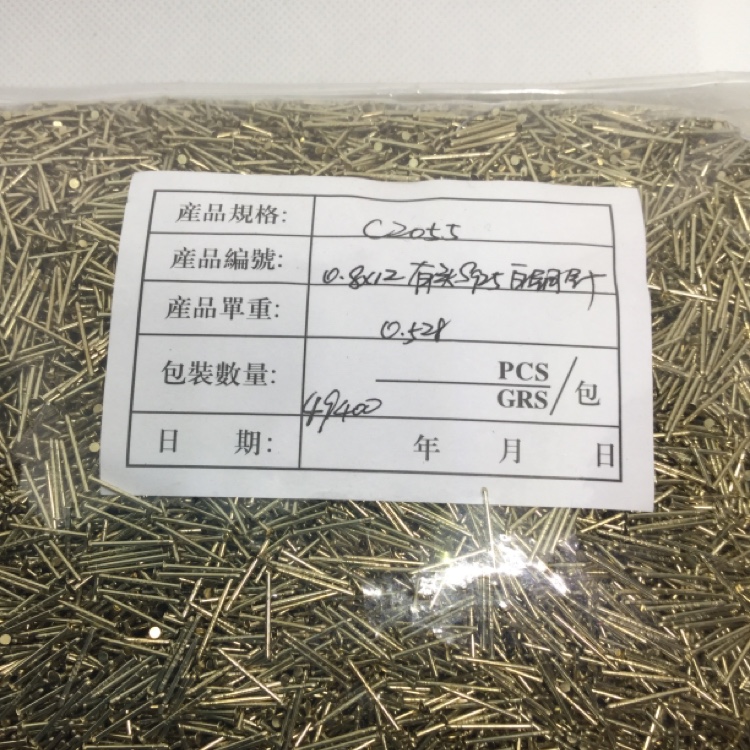

This specially designed 0.8*12 white copper needle is based on this excellent foundation and the birth of the work. It not only retains the original characteristics of S925 white copper, but also further improves the accuracy and durability. The small but sturdy design allows it to work with ease in very small operating environments, such as embroidery, hand beading, and complex electronic component assembly.

Compared with the traditional distribution model, our factories sell directly to the end user, eliminating the additional cost burden caused by the middle link. This allows every customer to enjoy more affordable price concessions, while also being able to quickly respond to changes in market demand to adjust inventory quantities. For friends who need to purchase large quantities or replenish goods on a regular basis, this way of cooperation is undoubtedly more convenient and efficient.

In addition, due to the reduction of uncertain factors in the circulation chain, product quality can also be better controlled and tracked. From the selection of raw materials to the final packaging, every step is strictly followed by standard operating procedures (SOP), so as to minimize the probability of defective products.

In order to provide customers with the most satisfactory product experience, we have taken a series of strict measures in the production process to ensure that every white copper needle meets the expected standards. The first is to start from the source-to select top-grade cupronickel raw materials with purity of more than 92.5 for processing and forging; The second is to use advanced numerical control machine tool equipment to complete the cutting and polishing process in the molding stage to ensure extremely high dimensional consistency. Finally, it will go through several rounds of detailed inspection to eliminate unqualified items before it can be officially put on the market.

In the face of a wide range of market choices, how should you decide which one is best for you? The following suggestions may help you make an informed decision:

-Clear scope of use: Determine the required thickness specifications and hardness parameters according to the actual application scenario.

-Pay attention to the difference in details: check whether the surface smoothness and flatness are up to standard.

-Consider brand reputation: give priority to products from established manufacturers that have a good reputation.

In recent years, with the rapid spread of DIY culture around the world, the concept of "do-it-yourself beauty" is deeply rooted in the hearts of the people. Driven by this trend, small objects such as S925 white copper needles, which are both beautiful and practical, are increasingly popular. They are not only the right-hand man in the hands of professional craftsmen, but also a good helper for many young lovers to express their personal taste.

In the future, we can foresee that such products will continue to develop and improve along the route of technological innovation to meet more diversified demand expectations. If you are looking for a cost-effective S925 white copper needle, please do not hesitate to contact us for more information!